DURATEK AXLE DIFFERENCE IS IN THE PERFORMANCE

Details can make all the difference. Duratek prides itself on being a traditional American manufacturer, with real people who favor precision, not just mass production. On the road, a little shortcut taken by the manufacturer can make a huge difference in performance. That’s why we’re dedicated to being thorough and precise. See what makes us an innovator and industry leader.

Self-Adjusting Brakes

Duratek axles are set apart in the fact that we offer self-adjusting brakes as standard with our axles. We live in a world where there is no extra time to waste. We know that you don’t have the time to climb under your trailer to adjust the brakes with some tool that no one has even heard of. To give you the peace of mind, and save the time and effort, we offer self-adjusting brakes standard on all of our brake-equipped axles. Never adjusting means no worries and no time wasted. We pride ourselves in being the only large-scale axle manufacturer to offer self-adjusting brakes as standard.

Grease Cavity

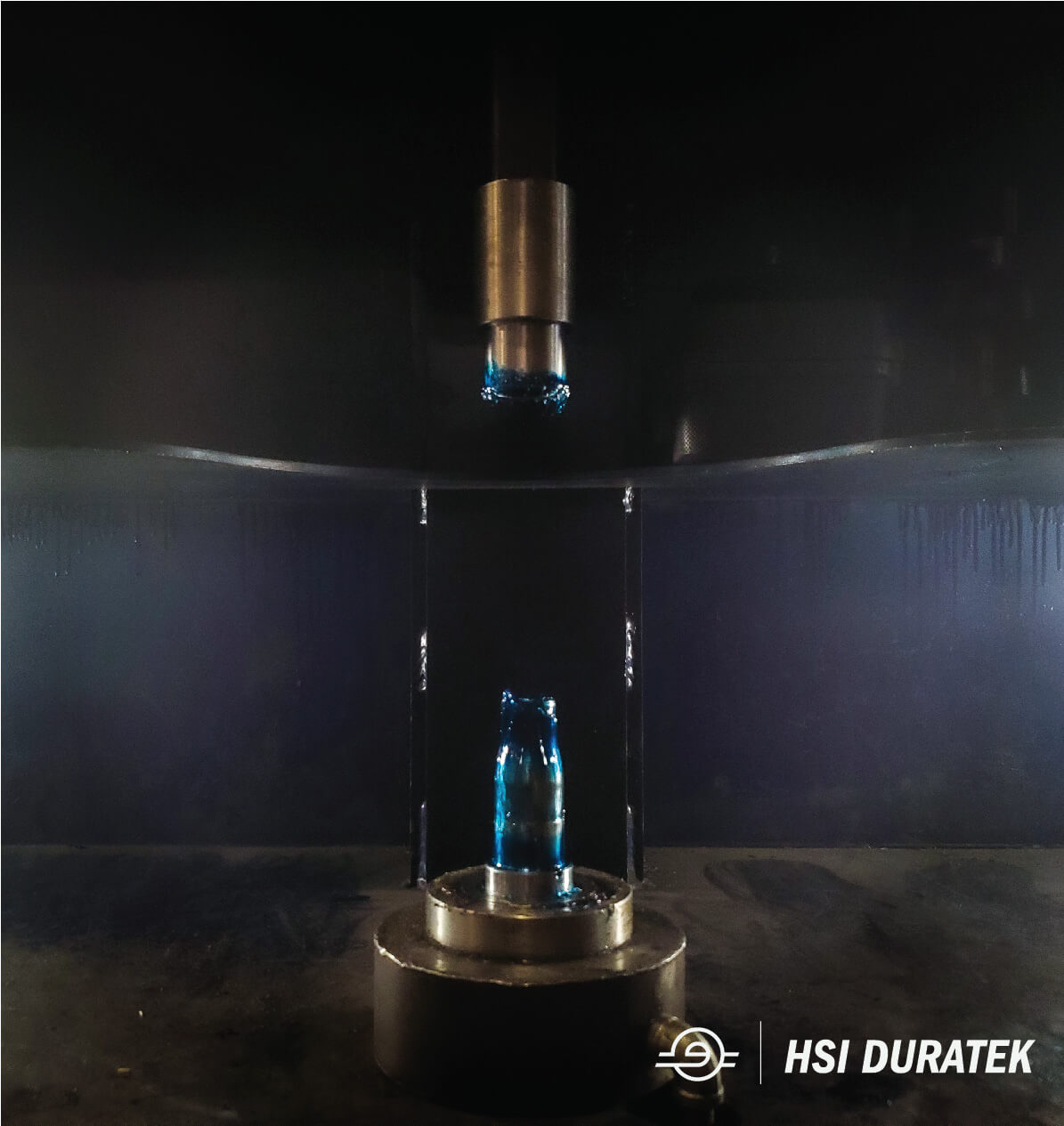

Duratek uses a unique process to make sure that the hub and bearing assembly is correctly lubricated. The industry standard process for bearing greasing takes a stack of bearings and pushes greases through the top bearing downwards until the grease reaches the bottom bearing. The bearings are greased while not in the hub. These bearings are sufficiently greased, but it leaves a cavity (the space between the bearings) when placed into the hub. This gives space for condensation to form, harming the bearings, and affecting your trailer’s performance. Furthermore, when the end user uses the easy lube, they may have to put 40 – 50 pumps of grease before it lubes the outer bearing. However, at Duratek, we use a custom in-house built machine that uses a special technique to grease the inner and outer bearings and the cavity. The hub assembly is set on top of a special spindle that is the right size for that specific hub. The modified spindle then injects the perfect amount of grease through both bearings, and the spindle cavity, so when it is installed, the complete hub is full of grease. Each hub is done individually to ensure that it is done with the utmost quality.

Image Above: A fully greased Duratek Hub

Image Above: Duratek’s custom made grease press

Image Above: A section view of a hub and the grease cavity.

Why Buy Duratek Axles?

We leave no stone unturned when it comes to our axle quality. We know our customers are searching for the best axles out there, and you have to go above and beyond to be one of the greats. That’s why the team at Duratek is committed to building your axles with high-quality parts and with precision techniques that few other manufacturers could offer you. Safety, strength, and reliability are our priorities, and we will stop at nothing to deliver exactly that: quality parts, excellent service, and fast turnaround times.

That is the Duratek difference.

Order your axles here.